|

Unique Transmission Equipment(Luoyang)Co., LTD

|

customized large size 32inch worm gear slewing drive slew drive for heavy equipment

| Price: | 2000.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The worm gear slewing drives designed and produced by U-TRSM are available in SE/PE, WE, WEA and other series.

1. Company introduction

Unique Transmission Equipment (Luoyang) Co., Ltd. is an innovative technology company that designs, develops and produces slew drives and Slewing rings. We have a wide range of standard series products to choose from, we also focus on customized slew drive and slewing rings solutions.

Since its establishment, Unique Transmission has won the trust and support of many customers with its high-quality products, excellent slewing scheme design capabilities and quick response services. Unique Transmission can provide not only slew drive products and design solutions, but also provide motors, hydraulic motors and other accessories, as well as various machining products.

2. Worm Gear Slew Drive Introduction

The slewing drive is a special rotary reduction product derived from the slewing ring product with high integration and large gear ratio, simple structure, easy use and maintenance.

Slewing drive can be divided into gear drive and worm gear worm shaft drive according to different transmission forms. According to the different closed form of worm gear, it can be divided into open and closed two types.

The worm gear slewing drives designed and produced by U-TRSM are available in SE/PE, WE, WEA and other series. The slewing drive can also be equipped with hydraulic motors, AC motors, DC motors, servo motors, stepping motors, etc. The bases of the slewing drives have open type and closed type. Generally, the open structure slewing drive is mostly used in applications where the environment is too wicked and the maintenance and maintenance cycle is short. The open structure slew drive is more convenient for inspection, maintenance and service of the machine parts, also more convenient to replacement. However, the closed structure can provide longer service life in occasions where the environmental conditions have not changed much and the environmental pollution level is below the medium level.

3. Slewing Drive Parameters As Below:

| Data Model | Output Torque | Tilting Moment Torque | Holding Torque | Static Axial Rating | Static Radial Rating | Dynamic Axial Rating | Dynamic Radial Rating | Gear Ratio | Tracking Precision | Weight |

| SE3/PE3 | 400 N.m | 1100 N.m | 2000 N.m | 30 KN | 16.6 KN | 9.6 KN | 8.4 KN | 62:1 | ≤0.2°/≤0.12° ≤0.15° | 12 Kg |

| SE5/PE5 | 600 N.m | 2800 N.m | 5000 N.m | 45 KN | 22 KN | 14.4 KN | 11.1 KN | 62:1 | ≤0.2°/≤0.08° ≤0.12° | 16 Kg |

| SE7/PE7 | 1500 N.m | 13500 N.m | 10400 N.m | 133 KN | 53 KN | 32 KN | 28 KN | 73:1 | ≤0.2°/≤0.07° ≤0.11° | 25 Kg |

| SE9/PE9 | 6.5 KN.m | 33.9 KN.m | 38.7 KN.m | 338 KN | 135 KN | 81 KN | 71 KN | 61:1 | ≤0.17°/≤0.07° ≤0.09° | 49 Kg |

| SE12/PE12 | 7.5 KN.m | 54.3 KN.m | 43 KN.m | 475 KN | 190 KN | 114 KN | 100 KN | 78:1 | ≤0.17°/≤0.05° ≤0.07° | 61 Kg |

| SE14/PE14 | 8 KN.m | 67.8 KN.m | 48 KN.m | 555 KN | 222 KN | 133 KN | 117 KN | 85:1 | ≤0.17°/≤0.05° ≤0.07° | 64 Kg |

| SE17/PE17 | 10 KN.m | 135.6 KN.m | 72.3 KN.m | 970 KN | 390 KN | 235 KN | 205 KN | 102:1 | ≤0.15°/≤0.05° ≤0.07° | 105 Kg |

| SE21/PE21 | 15 KN.m | 203 KN.m | 105.8 KN.m | 1598 KN | 640 KN | 385 KN | 335 KN | 125:1 | ≤0.15°/≤0.05° ≤0.07° | 149 Kg |

| SE25/PE25 | 18 KN.m | 271 KN.m | 158.3 KN.m | 2360 KN | 945 KN | 590 KN | 470 KN | 150:1 | ≤0.15°/≤0.05° ≤0.07° | 204 Kg |

| WE9 | 8 kN.m | 35.6 kN.m | 38.7 kN | 578 kN | 215 kN | 136 kN | 115 kN | 62:1 | ≤0.15° | 48.5 Kg |

| WE12 | 9.5 kN.m | 57 kN.m | 43 kN | 760 kN | 280 kN | 190 kN | 148 kN | 79:1 | ≤0.15° | 61 Kg |

| WE14 | 10.8 kN.m | 71.2 kN.m | 48 kN | 960 kN | 360 kN | 230 kN | 200 kN | 86:1 | ≤0.13° | 68 Kg |

| WE17 | 12.96 kN.m | 142.4 kN.m | 72.3 kN | 1166 kN | 435 kN | 280 kN | 231 kN | 104:1 | ≤0.1° | 90 Kg |

| WE21 | 28.7 kN.m | 203 kN.m | 105.8 kN | 1598 kN | 640 kN | 385 kN | 335 kN | 90:1 | ≤0.1° | 169 Kg |

| WE25 | 34.2 kN.m | 310 kN.m | 158.3 kN | 2360 kN | 945 kN | 590 kN | 470 kN | 104:1 | ≤0.1° | 199 Kg |

| WEA7 | 3.5 kN.m | 14.2 kN.m | 20 kN | 220 kN | 90 kN | 63 kN | 48 kN | 47:1 | ≤0.15° | 35 Kg |

| WEA9 | 8 kN.m | 35.6 kN.m | 38.7 kN | 578 kN | 215 kN | 136 kN | 115 kN | 62:1 | ≤0.15° | 53 Kg |

| WEA12 | 9.5 kN.m | 57 kN.m | 43 kN | 760 kN | 280 kN | 190 kN | 148 kN | 79:1 | ≤0.15° | 66.8 Kg |

| WEA14 | 10.8 kN.m | 71.2 kN.m | 48 kN | 960 kN | 360 kN | 230 kN | 200 kN | 86:1 | ≤0.13° | 75 Kg |

| WEA17 | 12.96 kN.m | 142.4 kN.m | 72.3 kN | 1166 kN | 435 kN | 280 kN | 231 kN | 104:1 | ≤0.1° | 96 Kg |

| WEA19 | 18.5 kN.m | 196 kN.m | 86.7 kN | 1800 kN | 675 kN | 290 kN | 250 kN | 93:1 | ≤0.1° | 130 Kg |

| WEA21 | 28.7 kN.m | 203 kN.m | 105.8 kN | 1598 kN | 640 kN | 385 kN | 335 kN | 90:1 | ≤0.1° | 172 Kg |

| WEA25 | 34.2 kN.m | 310 kN.m | 158.3 kN | 2360 kN | 945 kN | 590 kN | 470 kN | 104:1 | ≤0.1° | 202 Kg |

4. Packing Way

1. Apply anti-rust oil on slewing drives ; 2. Using wrapping belts to package the slewing drive; 3. Place the packaged slewing drives to the plywood cases; 4. Using pearl cotton to fix the slewing drives in the boxes and confirm the products will not move during transportation; 5. Using packing belts to pack the wooden cases; 6. Stick the shipping marks to let our customers identify goods easily.

5. Application Area

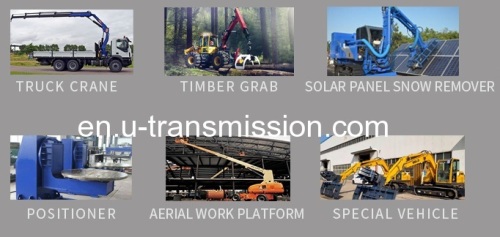

Spur gear slew drives applications mainly include industrial robots, machine tool turrets, cranes, truck-mounted cranes, automated production lines, light machines, radar cars, positioners, flexible bending machines, grass grabs, solar panel snowplows, forestry machinery, agricultural machinery and other fields. You can also check our mounting videos to learn how to use it.

6. Transportation: By sea/ air/ rail/ road/ TNT/DHL/UPS/Fedex, all acceptable.

7. Contact information

Unique Transmission Equipment (Luoyang) Co.,Ltd

Address: No.22 Binhe Road, New & High Tech Industry Development Zone,

Luoyang Area Of China(Henan) Pilot Free Trade Zone, 471000